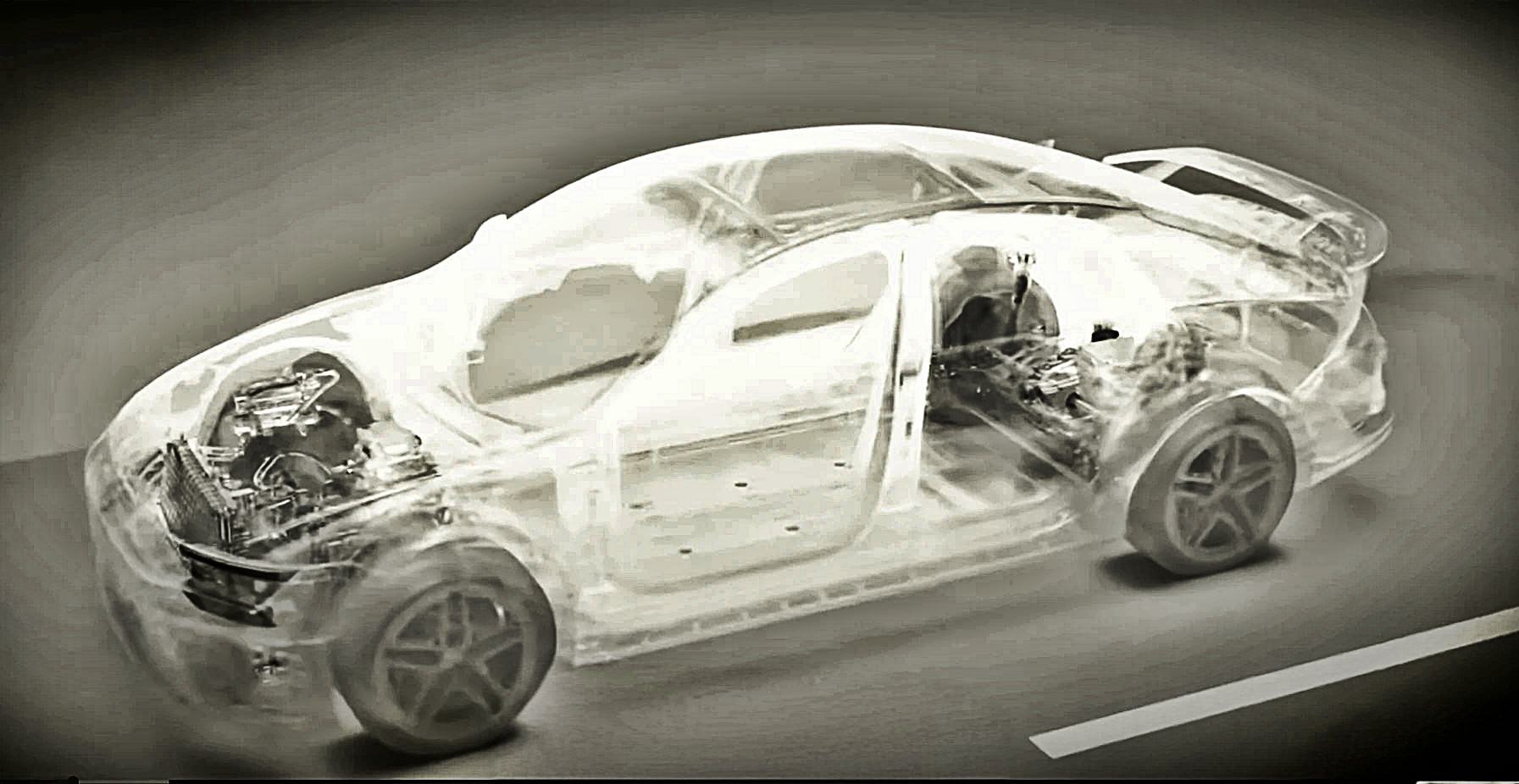

Although it may seem that the drivetrain in fully electric vehicles is essentially one or two electric motors powered by a rechargeable battery pack, there are varying configurations which have been developed by different automakers. These give different levels of performance and efficiency to enhance the EV driving experience.

Global EV game-changer

The 2-Stage Motor System developed by Hyundai Motor Group (HMG) is an advanced electric drivetrain which the automaker presents as a global EV game-changer. Said to be the only set-up of its kind to achieve both high performance and efficiency, its advanced technology represents a major leap forward in EV engineering, delivering thrilling driving experiences without compromising sustainability.

At the heart of this system are three essential components:

♦ The inverter – converts DC power from the battery into AC power for the motor

♦ The motor – generates rotational force

♦ The reducer – transfers this force to the wheels

An EV’s power output depends on the voltage and current the battery can deliver to the motor (or motors) via the inverter. Traditionally, increasing current resulted in heavier propulsion systems and greater heat management challenges. Motor systems optimized for high output in this way often compromise efficiency during everyday driving, but Hyundai Motor Group’s R&D innovations have overcome this challenge by rethinking the inverter.

Duel inverters

The 2-Stage Motor System features a dual inverter structure equipped with 12 semiconductor switches in a ‘6 plus 6’ configuration, doubling the conventional count. One set of six switches uses silicon carbide semiconductors for high efficiency, while the other set uses silicon semiconductors to support high-power conditions.

This configuration increases the voltage that can be supplied to the motor by up to 70%, enabling a higher power output without compromising efficiency. The system operates intelligently based on Hyundai Motor Group’s smart dual-mode control. Proprietary control algorithms ensure seamless transitions between the two modes.

Doubling the number of switches was not just a hardware upgrade – it required a complete redesign of the control system. A conventional 6-switch inverter operates in eight combinations, but with 12 switches, the combinations multiply eightfold, demanding far more precise coordination and control.

Managing the complexity

Proprietary algorithms manage this complexity, smoothing voltage transitions and delivering seamless, uninterrupted and powerful performance. The system uses a transfer switch to shift seamlessly between modes, ensuring strong power when accelerating and high efficiency during long-distance driving.

Compact, high-performance design

Despite the added complexity, the inverter remains compact thanks to HMG’s in-house power module design. Each module houses the power semiconductor switches and provides packaging that ensures heat dissipation and electrical insulation.

To achieve a smaller, lighter inverter, HMG integrated nine modules into three, reducing size and weight while maintaining durability. The cooling system was also enhanced with a double-sided setup, significantly improving heat dissipation. This enhancement allows for higher power density within a smaller package, enabling high output without increasing overall dimensions. These optimizations mean the 2-Stage Motor System delivers cutting-edge capability while remaining practical for mass production.

Available today

The 2-Stage Motor System is already powering high-performance EV models such as the Hyundai IONIQ 5 N, IONIQ 6 N, IONIQ 9, and the latest NEXO FCEV. Kia also offers it in their EV6 GT, EV9, and EV9 GT.

![Hyundai NEXO FCEV [2026]](https://www.motaauto.com/wp-content/uploads/2025/11/Hyundai-NEXO-FCEV-2026-300x202.jpg)