Although PROTON, as a national car corporation, has been making its own vehicles in Malaysia since the very start, its transition to electric vehicles started off with importing EVs – the e.MAS 7 being the first one – made in China at a Geely factory. Nevertheless, this was only a short-term necessity as the automaker already had plans to make its EVs locally.

Within less than a year of the launch of its first EV, PROTON will be producing its first EVs at a new plant at its Tanjung Malim manufacturing complex in Perak. The new factory, which had its groundbreaking ceremony just 6 months ago, is nearing completion and the first EVs are expected to roll out during September 2025.

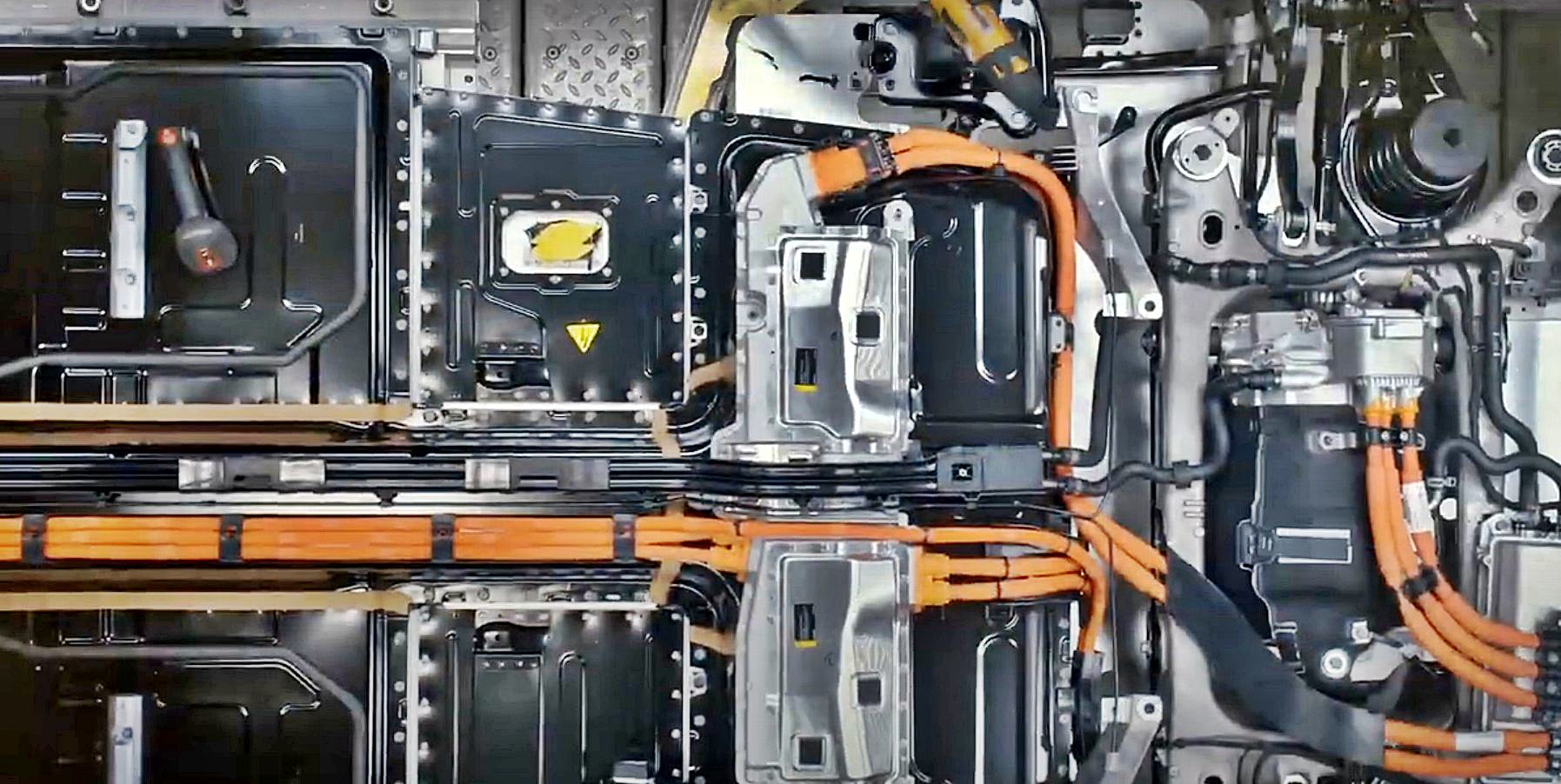

Although the main factory making models such as the X-series SUVs, S70, Iriz and Persona has a large capacity, it is necessary to have a dedicated factory for producing EVs due to their different nature. Special attention is needed for areas where high-voltage batteries and systems are installed to ensure safety for the workers.

The layout is designed to accommodate flat EV underbodies and electric drive units, featuring dedicated zones, enhanced safety, and flexible line configurations for future scalability.

Geely, as DRB-HICOM’s partner in PROTON, has provided technical guidance on production systems, helped with equipment selection, and deployed experts to assist with installation and trial runs. The Chinese automaker has also facilitated overseas training for PROTON staff and ensured the plant aligns with global EV manufacturing standards. This guarantees the plant meets current needs and offers long-term scalability.

Expansion up to 45,000 units

The plant, which has an initial investment of RM82 million, has been designed with scalability in mind, allowing for flexible adaptation to future models and production volumes. The annual capacity will start off at 20,000 units and as time goes by and demand increases (as it surely will with more people switching to EVs), the volume can be increased up to 45,000 units annually.

For key areas, each line could add several stations, with their tester lines being modular and capable of accommodating platform variations or multi-model production. In the logistics area, the plant is capable of future expansion, with its logistics flow and storage systems optimized to support both local and export markets.

Infrastructure such as utility systems, material handling paths, and digital traceability tools like Manufacturing Execution System and Warehouse Management System are already in place to support future upscaling without significant redesign.

As with the original establishment of PROTON, there will be a strong focus on the local workforce which will see the creation of over 200 new jobs, specialising in EV industrialisation and technical services, for the local community. To strengthen its local talent pipeline, PROTON is collaborating with Polytechnic Sultan Azlan Shah by providing technical syllabus input and supporting hands-on training initiatives. This partnership helps aligning academic learning with industry needs and supports long-term workforce development.

The new plant will produce multiple models which use the Global Modular Architecture platform. Following the e.MAS 7 will be the e.MAS 5, with another 3 models now under planning for future inclusion.

![Proton e.MAS 7 Prime EV [2025]](https://www.motaauto.com/wp-content/uploads/2025/02/Proton-e.MAS-7-Prime-EV-2025-85.jpg)

![Proton e.MAS 5 EV [2025]](https://www.motaauto.com/wp-content/uploads/2025/08/Proton-e.MAS-5-EV-2025-15.jpg)

“This plant symbolizes PROTON’s transformation and our unwavering commitment to a sustainable, high-tech future. We are also laying the foundation for Malaysia’s leadership in the regional EV landscape by strategically expanding our EV offerings into new overseas markets. This is a monumental step for the company and for the nation, and we are excited to see our first Malaysian-made EVs to roll off the line and onto our roads,” said Wan Yousry bin Mohamed, Head of PROTON’s Manufacturing Engineering.

![Proton EV factory [2025] (2)](https://www.motaauto.com/wp-content/uploads/2025/08/Proton-EV-factory-2025-2-696x392.jpeg)