An opening chapter in the history of PROTON, Malaysia’s first national automaker, has been closed with the end of production operations at its factory in Shah Alam, Selangor.

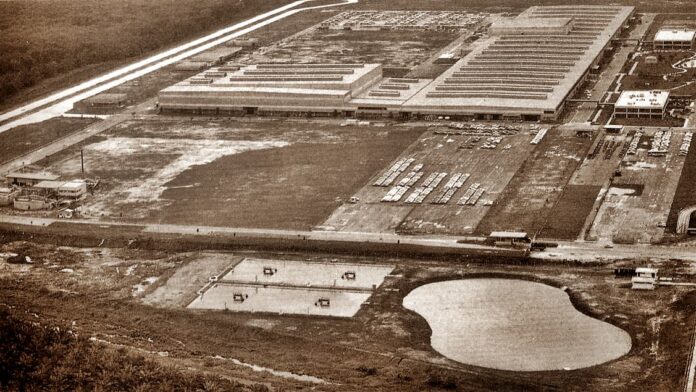

The factory, which began producing the first Malaysian National Car – the Proton Saga – in 1985, was built with an investment of around RM370 million. It was a full-fledged vehicle manufacturing facility, the first of its kind in Malaysia as all other vehicle production facilities were assembly plants. This meant that there were processes such as casting and powertrain manufacturing, as well as stamping of body panels.

Besides manufacturing, the factory complex also housed PROTON’s Research & Development Centre, PROTON DESIGN, and had the first purpose-built vehicle test course in Malaysia.

The initial annual production capacity was 85,000 units a year in 1985 and then increased to 120,000 units in 1992. Thereafter, the capacity was gradually increased until it reached 180,000 units a year by 1996. The factory was running at maximum capacity and demand was so great that AMI, another assembly plant in Shah Alam, was contracted to assemble the Saga Aeroback briefly.

Adding production capacity

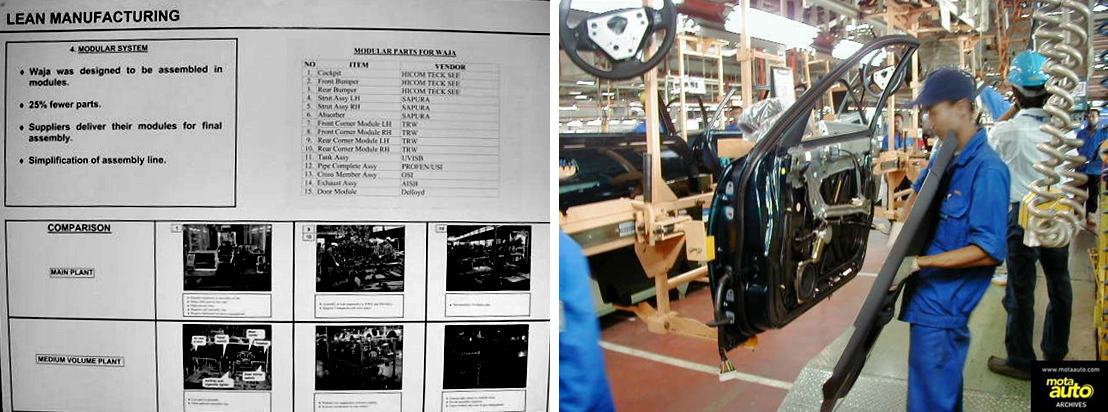

The following year, with the addition of a medium-volume factory (MVF) on the 83.48-hectare complex site, another 50,000 units a year were added for a total of 230,000 units annually. The MVF, covering 40,600 sq. metres, not only provided additional capacity but also used the new modular assembly and lean manufacturing approach to vehicle production. The first all-new model to be produced from this facility was the Waja.

Firat million units in 11 years

From the roll-out of the first unit in July 1985, it took 8 years for the factory to produce its 500,000th car (a Wira) in July 1993. Just 3 years later, the 1 millionth unit (a Putra) was completed at the AMM plant in Pahang.

Production in the East Coast

While the majority of models were produced at the factory in Selangor, some models such as the Satria, Putra, Tiara and Juara were produced at the AMM plant in Pekan, Pahang (known as HICOM Automotive Manufacturers today). These models were marketed by a joint venture company called Usahasama Proton-DRB (USPD) which would later be acquired by PROTON and become Proton Edar.

With the end of operations at the Shah Alam factory, production of Proton vehicles will be done only at the Tg. Malim, Perak manufacturing complex. The final production unit at the Shah Alam factory was a Saga, which left the line on September 30, 2025. Some 1,400 employees from Shah Alam have joined their colleagues at the Tg. Malim factory which is at the core of the Automotive High-Tech Valley (AHTV).

The Tg, Malim complex in Perak

The Tg. Malim factory was built at a cost of RM1.8 billion and was to have started operations in August 1998. However, due to the Asian financial crisis, the factory’s completion was delayed till 2003. Its 1,280-acre site was planned as part of Proton City, which would cover 4,000 acres and have residential, commercial, institutional, industrial and recreational areas.

The bigger picture was that Proton City would be like other automotive industrial hubs such as Detroit in America and Rayong in Thailand where supporting industries would also be clustered around the factory. With the AHTV, it is now becoming a reality.

The Tg. Malim factory started off with a modest production capacity of 150,000 vehicles, but was expected to grow to 1 million vehicles a year in the future. However, it remained under-utilised and in 2011, only around one-third of the capacity was being used as demand patterns changed.

Upgraded after 2017

After Geely became DRB-HICOM’s partner in PROTON in 2017, a major exercise was carried out to upgrade the factory in preparation for a new generation of models such as the X-Series SUVs. Like the Shah Alam factory, the Tg. Malim factory is a complete manufacturing facility with advanced manufacturing processes and operates on an Industry 4.0 ethos. It has Malaysia’s largest mechanical press in the stamping division and an engine assembly line which was the first outside China to produce the 1.5-litre TGDi engine used in the X50.

Leveraging on a production capacity of 250,000 units a year, PROTON continues to strengthen local vendor networks and the ecosystem through aggressive component localisation. With its strategic scale, the factory serve as the primary right-hand drive export hub for the Geely Group in Southeast Asia.

Dedicated EV factory

In September, this year, a dedicated factory to assemble electric vehicles was completed and is now assembling the e.MAS7 and e.MAS 5. The new factory has an initial investment of RM82 million (with RM47 million utilised in the first phase). The annual capacity will start off at 20,000 units and as time goes by and demand increases (as it surely will with more people switching to EVs), the volume can be increased up to 45,000 units.