For over 100 years, the auto industry has used the internal combustion engine (ICE) for its vehicles. In the 21st century, there is a major shift away from ICE towards electrified powertrains. This change has been brought on not just by the awareness that supplies of fossil fuel – petrol and diesel – are diminishing. That became clear during the energy crises of the 1970s which led the industry to make engines more fuel-efficient.

While the diminishing supply of fossil fuel is one reason for stopping use of ICE, the more urgent reason is climate change, ironically being influenced by emissions from ICE vehicles. Apart from toxic elements in exhaust gases that come from the combustion process, carbon dioxide (CO2) is also released into the atmosphere.

This gas – referred to as a ‘greenhouse gas’ – has been rapidly increasing over the decades and it has started to affect the climate. It traps heat and this is causing temperatures to rise. Scientists have forecast that continued increases in average temperatures will reach a point when continued life on the planet will be threatened and action has to be taken now.

This has led to commitments by countries and industries to take actions that will prevent climate change from reaching the ‘tipping point’. While many countries have formulated policies of decarbonisation with phased actions over the next few decades, the auto industry has also made commitments towards achieving carbon-neutrality in not just their vehicles but also in every aspect of their industry, including manufacturing.

Toyota’s commitment

As one of the global leaders in the auto industry, with the largest volumes of sales each year, Toyota Motor Corporation has a strong responsibility towards addressing climate change. In fact, its attention to protecting the environment has been ongoing for many decades. As part of its aim of making ever better cars, it has constantly strived to make them more environment-friendly by bringing down fuel consumption and reducing harmful emissions in exhaust gases.

As far back as the early 1990s, Toyota wanted to make a big leap in fuel efficiency as a groundbreaking advancement going into the 21st century. It aimed to double fuel efficiency numbers during the decade. It was a tall order by top management and the engineers of the G21 project (as it was known) tried various approaches, including making improvements to engines.

While many different powertrains were explored and tested, it was important to ensure that the chosen one would be reliable and affordable because Toyota produces cars in the millions. Whatever powertrain was finally chosen would have to have the same high standards of quality, durability and reliability that Toyota has built its strong reputation on.

Engine improvements had limits and the target of doubling fuel efficiency could not be reached with just that approach. It was then decided to go for a hybrid powertrain – a combination of ICE and an electric motor which work together to generate power. It’s an idea that was around for decades but was not developed sufficiently to be commercialised in mass production.

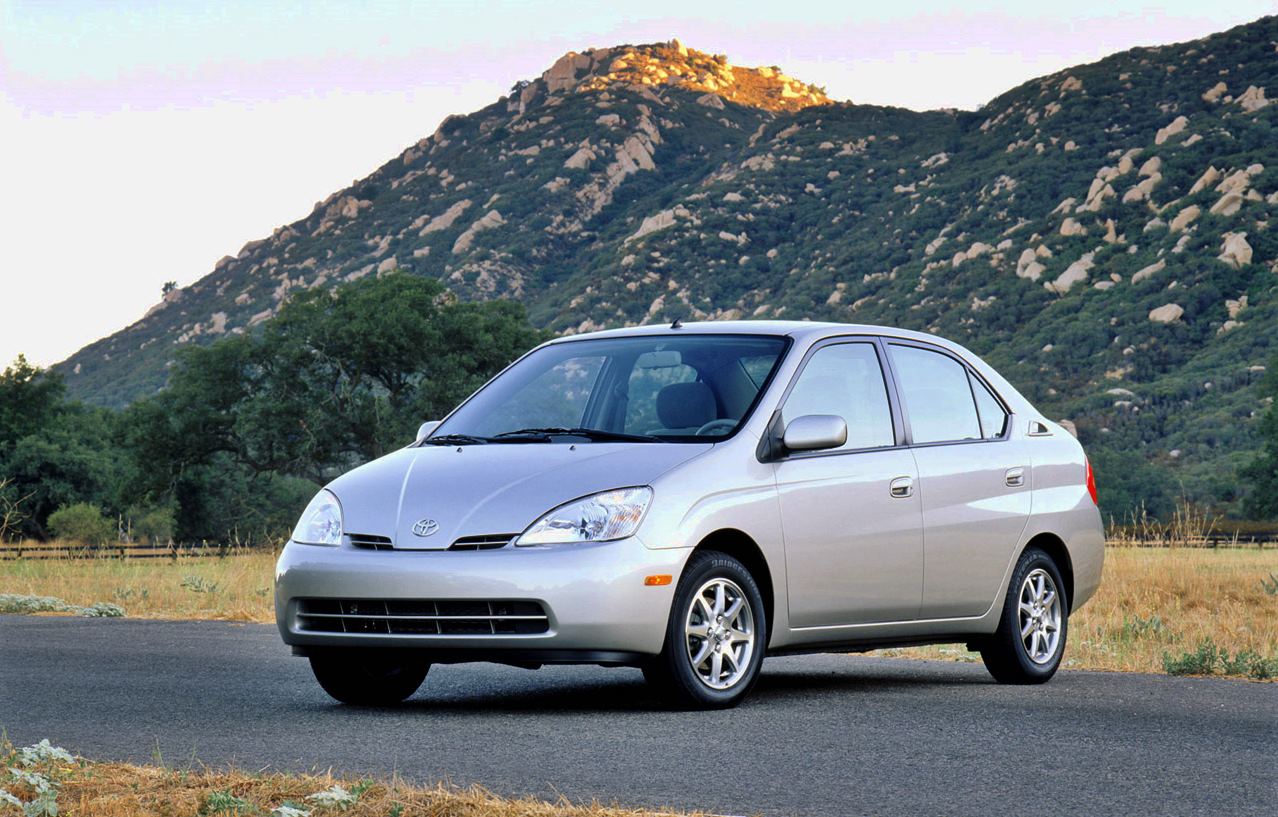

The project took a basically unproven technology all the way to mass production. The model that was developed with a hybrid electric powertrain was the Prius, and it would be the world’s first mass-produced hybrid electric passenger vehicle. In the months leading up to the launch of the Prius in Japan in December 1997, Toyota’s advertising for the new model included the catchphrase: ‘Just in time for the 21st century’.

Proven advantages of HEV

The advantage of a hybrid electric powertrain became more apparent as early data came in from real-world usage. The targeted doubling of fuel efficiency was confirmed by many owners, and in the UK, there were reports of up to 21 kms/litre with the Prius.

This was not surprising since the engine size was just 1.5 litres and it did not run constantly as the electric motor also provided power. Furthermore, the powertrain automatically shut down during extended periods of idling and started up when it was time to move forward. This ‘auto-stop’ feature is common in many of today’s cars and helps to save fuel.

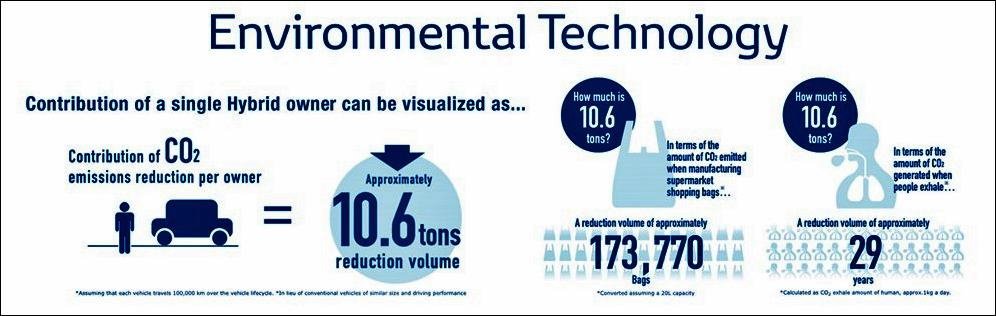

The reduced use of the engine also meant less exhaust gases being generated, lowering the amount of CO2 and other undesirable gases into the atmosphere.

With the advantages of hybrid electric technology proven, Toyota began to improve and advance the technology, offering it in more models. The environment-friendliness of the powertrain and the fact that the Prius and other hybrid electric models behaved like ICE cars and required no change in driving style made acceptance of the technology easier.

Multi pathway approach

Fast forward to 20 years after Toyota introduced the groundbreaking Prius and the automotive landscape has changed. Electrification has become commonplace in the industry and almost every Toyota model has a hybrid electric option. Almost half of the brand’s sales globally are of hybrid electric vehicles.

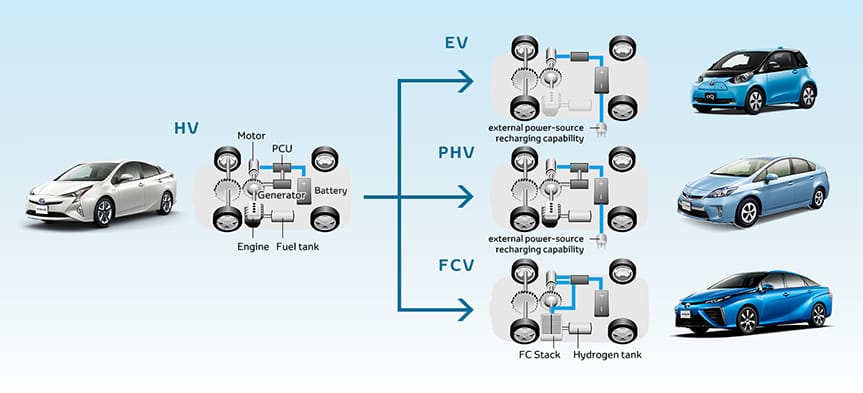

With the need to address climate change even more urgent, electrification is seen as the best solution to cutting carbon emissions which are a major cause of global warming, impacting the climate. However, Toyota does not regard full electrification as the only approach to take and instead offers a multi-pathway solution.

This approach takes into consideration the fact that different regions and markets have different economic conditions, and it is not realistic to use a ‘one size fits all’ approach where fully electric vehicles are the only choice. Not only do EVs cost more than ICE cars at this time but the charging infrastructure must also be sufficiently developed to support widespread use of EVs.

Toyota’s multi pathway approach offers different electrified solutions (as well as ICE) from fully electric vehicles to hybrid electric vehicles. In more advanced markets like Japan and Europe, there is the Mirai, a fuel-cell electric vehicle which runs on hydrogen.

But by far, it is hybrid electric vehicles (HEVs) which Toyota promotes widely because this approach is more accessible to a wider range of consumers due to the relatively lower cost of the vehicles. While HEVs are not zero emission vehicles, they still have much lower emissions than ICE vehicles, so they are still beneficial in the context of addressing climate change. This is because more people using HEVs will start the process of carbon reduction faster, rather than waiting for everyone to be able to afford or want to buy EVs.

The best solution for Malaysia

As mentioned earlier, Toyota’s multi pathway approach offers different mobility solutions for different markets. For Malaysia, HEVs are the ideal solution at this time when the country is just moving towards electrified mobility. Toyota’s HEV powertrain is self-charging, so there’s no need for the driver to look for a charging station as the battery is recharged automatically while the vehicle is running.

Of course, petrol is still necessary for the engine but with the electric motor also doing some of the work, the consumption is far lower than with an ICE vehicle, so motoring costs are also reduced.

HEV models currently offered by UMW Toyota Motor in Malaysia are the Toyota Corolla Cross Hybrid Electric, Corolla Cross HEV GR Sport, Innova Zenix Hybrid Electric, and Camry Hybrid Electric. Of these, the Corolla Cross, which is assembled locally, is among the bestselling HEVs in the market.